Assessing and reducing taste and odor issues in drinking water

By Tony Reid, PE

The presence of unpleasant tastes and odors in drinking water is a serious and increasingly frequent problem for water utilities in the U.S. The repercussions extend far beyond mere inconvenience. City and county officials responsible for managing water supplies have a sworn duty to their constituents to provide safe drinking water.

Fortunately, most tastes and odors found in drinking water are non-hazardous, and can be treated and/or eradicated using a combination of methods uniquely tailored to location and source. As a result, many public officials are taking action to resolve their ongoing water issues.

While many inorganic and organic compounds can produce unpleasant tastes and odors in water, the primary causes of these problems are two organic compounds associated with algal blooms: 2-Methylisoborneol (MIB) and geosmin, which are naturally produced by cyanobacteria (blue-green algae) and actinobacteria.

Both MIB and geosmin have a distinct, strong odor that can be characterized as earthy and musty. Typical odor threshold concentrations for MIB and geosmin are 9 ng/L and 4 ng/L, respectively, with a range of 6 to 10 ng/L. For most people, the threshold, or level at which most humans can detect these compounds, is about 10 ng/L.

In addition to MIB and geosmin, when an algal bloom occurs, the rapid growth and decay of bloom-forming algae species will also produce pigments that cause water discoloration and toxins that are harmful to humans and animals.

Few technologies address the unique combination of taste and odor, color and emerging contaminants issues since there are many compounds associated with each issue.

Anderson Regional Joint Water System

Anderson Regional Joint Water System

During a 2015-16 evaluation and design project for the Anderson Regional Joint Water System (ARJWS) in Anderson, S.C., Goodwyn, Mills and Cawood (GMC) of Greenville, S.C., was tasked with developing a cost-effective solution that would significantly lower concentrations of the taste- and odor-causing compounds. Until then, the facility had attempted to treat the taste and odor issue with copper- and peroxide-based algaecides as in-lake treatment, and the combination of powdered activated carbon (PAC)/chlorine dioxide (ClO2) as in-plant treatment, to no avail.

GMC used a phased approach in devising a solution:

- Phase I: research taste, odor and color, iron and manganese and emerging contaminants, evaluate current treatment process and develop a matrix for current issues versus treatment technologies

- Phase II: analyze identified technologies

- Phase III: provide treatment recommendations, along with expenditures, life-cycle cost analysis and a path forward

Four treatment alternatives were analyzed: ozone, ozone + peroxide, ultraviolet (UV) + peroxide, and ozone + peroxide + UV. GMC’s formulaic approach ultimately resulted in a treatment strategy that holistically addressed taste and odor, color and emerging contaminants. Ultimately, ozone + peroxide treatment was found to be the most viable option, with the ability to feed ozone alone and augment with peroxide for quenching ozone residuals.

What’s the Problem?

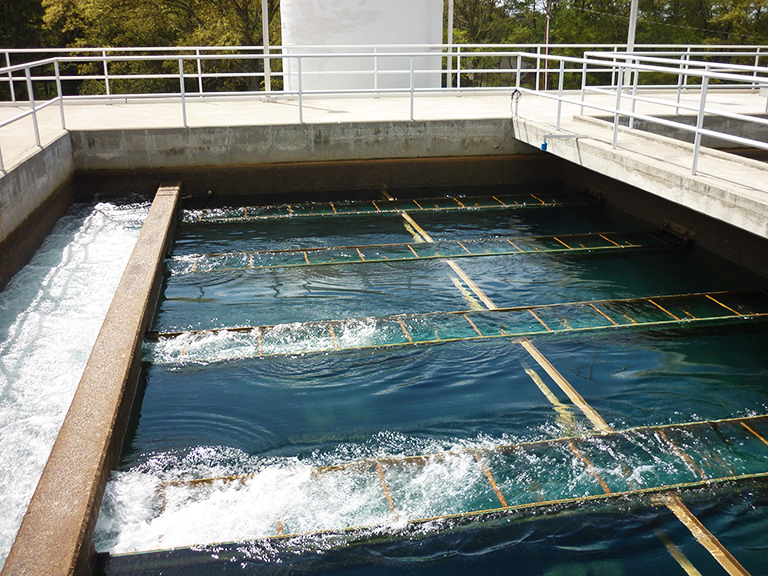

The ARJWS Water Treatment Plant (WTP) is a conventional surface water facility with combined flocculation and sedimentation basins followed by rapid multimedia filtration. The plant is supplied by surface water from Lake Hartwell, which lies along the border of upstate South Carolina and Georgia.

Treatment begins in Lake Hartwell with the algaecide application, but this was the only location outside of the facility property where treatment occurred. In June 2013, ARJWS began experiencing intermittent/seasonal taste and odor problems due to compounds found in Lake Hartwell, naturally produced by certain algae found in the lake.

The most common taste and odor compounds were MIB and geosmin, which have an earthy taste and noticeable odor even at low concentrations (<10 ng/L). However, concentrations entering the plant in the summer of 2014 were in the 300 to 700 ng/L range – meaning their removal below human detection through conventional treatment methods was nearly impossible.

While the ARJWS WTP utilized powdered activated carbon, chlorine dioxide and a mixed oxidant solution to adsorb and oxidize objectionable compounds, these technologies were limited in their ability to remove taste- and odor-causing substances at high concentrations. Therefore, the existing treatment process at the plant was not effective in removing taste- and odor-causing compounds, or emerging contaminants.

Finding a Solution

In August 2015, ARJWS retained GMC to provide a holistic solution that would address taste and odor within the treatment facility, in combination with the treatment occurring in the lake. Color spikes caused by the presence of iron and manganese were also addressed.

Subsequently, four oxidation processes were considered, including ozone and three advanced oxidation processes consisting of a select combination of ozone, hydrogen peroxide and/or UV light, to achieve the treatment goal. Bench-scale testing was performed to assist in determining contact time, chemical dose, equipment dimensions, equipment headloss, energy requirements, as well as capital and operational costs. A total of four rounds of testing were performed at varying oxidant doses and MIB concentrations. All technologies were effective at removing MIB from an influent concentration of 400 ng/L to 4 ng/L, which is below the human threshold. Greater concentrations were tested and in some events 99.7% removal of MIB was achieved with higher oxidant doses.

Based upon the review of the current treatment process, the implementation of an advanced oxidation process was found to be optimal. GMC subsequently recommended that a design for an ozone + peroxide treatment process, with the ability to feed ozone alone and augment with peroxide for quenching ozone residuals, be developed and constructed. Life cycle costs were performed, assuming an average flow rate of 20 million gallons per day (MGD) to account for operation and maintenance costs. Ozone feeding was found to be the least costly over the 20-year period at an estimated capital cost of $12.5 million and an annual operations and maintenance cost of $378,000. With the implementation of ozone at 4 mg/L, a raw water concentration of 400 ng/L could be observed and an effluent concentration of 4 ng/L of MIB could be observed leaving the treatment plant.

The addition of advanced oxidation process to AJRWS’ treatment process will allow for economical and efficient removal of taste- and odor-causing compounds while continuing to meet existing water treatment standards. Construction of the required structural components began in January 2017, paving the way for ARJWS to treat the seasonal taste and odor issues by spring 2018.

Although MIB and geosmin are difficult to remove with conventional treatment, multiple technologies are available that can remove them at varying levels – largely dependent upon factors unique to the treatment facility. For the best approach, facilities should be evaluated for the most cost-effective solution by comparing various treatment technologies. The cost for such an approach should not be a concern, as the evaluation can be completed at a fraction of the project’s cost.

About the Author

Tony Reid specializes in biological and physiochemical treatment in engineered systems and has been the process engineer for facilities in the industrial and municipal sectors. Since joining GMC in 2006, he has managed more than $40 million in construction and worked on more than $100 million in design projects. Notable projects include the Startex-Jackson-Wellford-Duncan Water District (SJWD) WTP membrane expansion in Lyman, S.C., and the Woodruff Wastewater Treatment Plant Improvements for The City of Woodruff. Notable projects currently under way include a water treatment plant and intake project in Walhalla, S.C and Laurens County, S.C., respectively.

Reid is a licensed Professional Engineer in South Carolina, Tennessee, Georgia and Alabama and an active member of the American Water Works Association and Water Environment Federation. He earned his bachelor’s degree in civil engineering from the University of South Alabama and master’s degree in environmental engineering from Clemson University.

GMC is one of the region’s largest privately-held architecture and engineering firms, with more than 375 employees. A regional firm with national experience, GMC is equipped to provide all of the services associated with architecture, engineering, environmental, geotechnical, interior design, landscape, planning, surveying and transportation.