Anderson, SC

ARJWS Advanced Oxidation Process Study and Upgrade

48 MGD, Ozone for 30 MGD

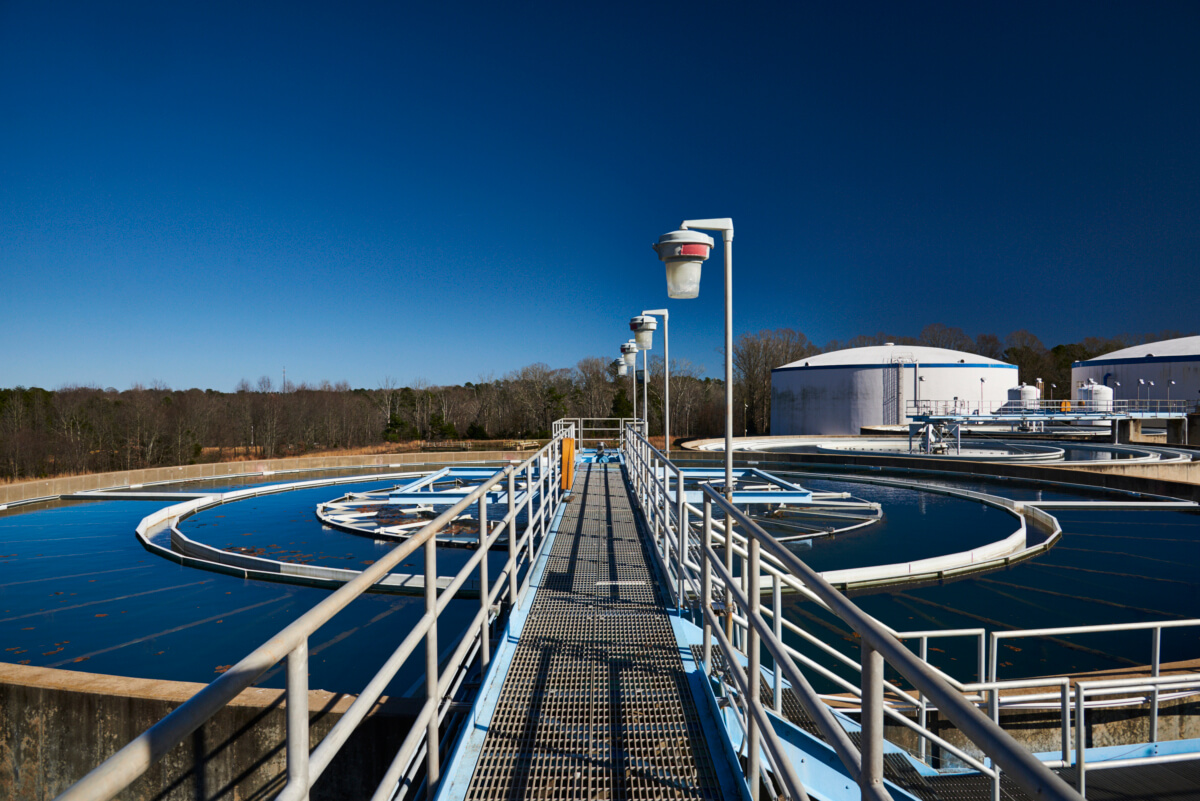

Anderson Regional Joint Water System (ARJWS) owns and operates a 48 MGD conventional water treatment facility on Lake Hartwell. ARJWS has experienced the need for process expansion as well as taste and odor treatment within the last five years. GMC has been involved in great detail in addressing both capacity and treatment issues.

GMC provided assistance to the ARJWS for a variety of needs including the engineering of the rehabilitation of the plant’s filters. The filter rehab has been a phased approach which consisted of the removal of the existing wheeler bottoms to bare concrete and installing low-profile filter underdrains as well as adding new media and air scour along with increased capacity. The filters were successfully high rated from 4.0 gal/SF to 5.5 gal/SF increasing the capacity of the facility.

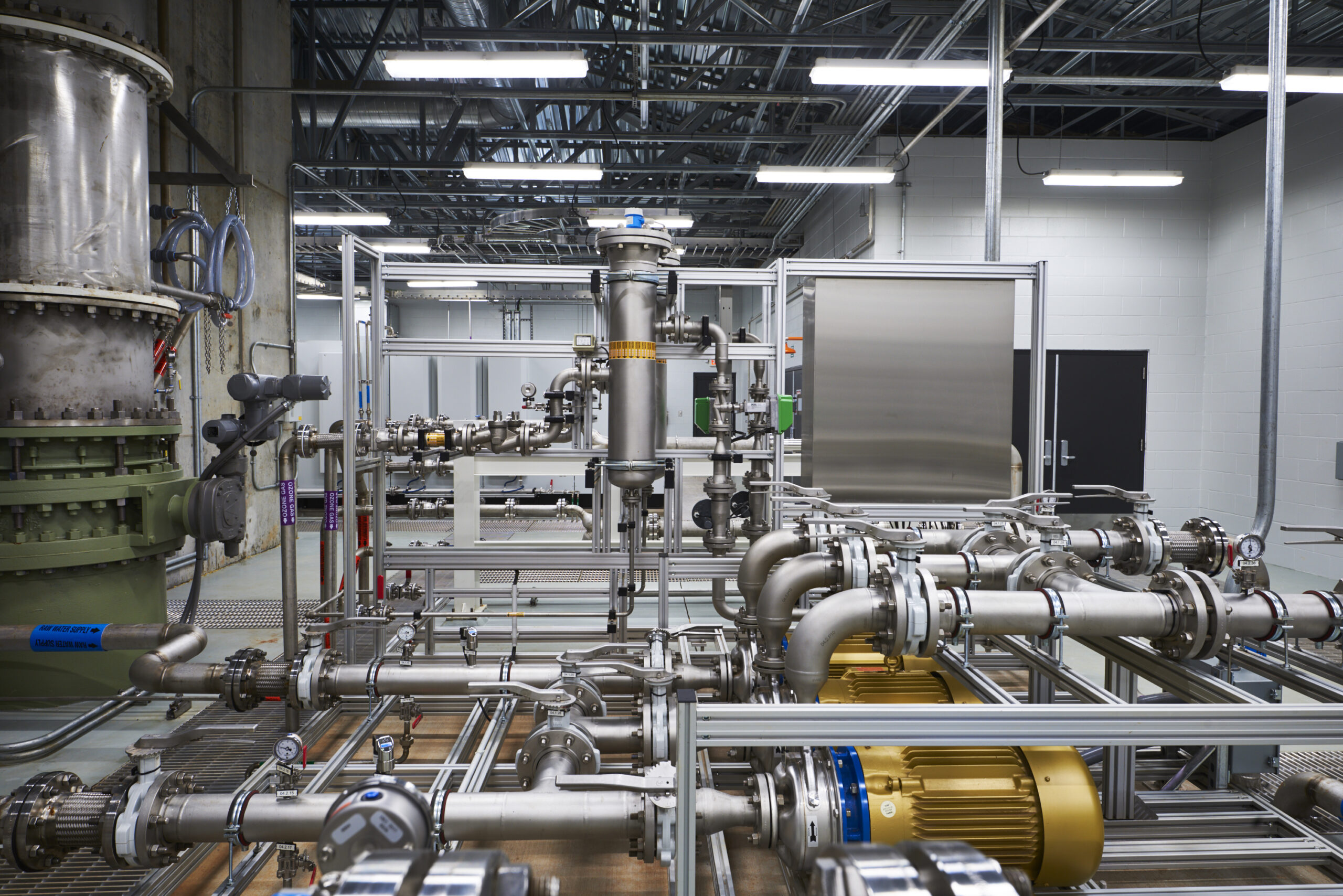

GMC performed a study to investigate treatment alternatives to combat taste and odor issues. As a result of the study, an advanced oxidation process (AOP) utilizing ozone and hydrogen peroxide was selected. Two 1,000-pound-per-day ozone generators were installed with a hydrogen peroxide dosing system for AOP and quenching. A concrete ozone contactor was constructed with a contact time of 10.7 minutes at 48 MGD.

A venturi injection system was selected to introduce ozonated water into the raw water achieving a minimum of 90% mass transfer efficiency. GMC teamed with Brasfield & Gorrie as the Construction Manager at Risk to deliver these process improvements to the ARJWS Water Treatment Facility. The project was completed on schedule and under budget.

In 2013, raw water drawn from Lake Hartwell began to see an increase in two forms of algae, MIB and Geosmin. The algae created newsworthy taste and odor issues and was untreatable with processes ARJWS had available at the time.

GMC devised a solution using a three-phased approach, which entailed 1) researching taste, odor and color, iron and manganese and emerging contaminants; evaluating processes and developing a matrix for current issues versus treatment technologies; 2) analyzing identified technologies; and 3) providing treatment recommendations with expenditures, life-cycle cost analysis and a path forward. Based on the study, GMC determined that an advanced oxidation/ozone system would address the taste and odor issues, while continuing to meet water treatment standards.

The project included new 30-inch and 36-inch raw water influent piping, a two-train concrete ozone contactor, liquid oxygen storage and vaporizing area, ozone generation process equipment, hydrogen peroxide advanced oxidation process (AOP) and quench process equipment, main process building, destruct building, associated instrumentation and electrical work in the new process building and existing main electrical building. Closely coordinated shutdowns of the raw water pipeline were necessary to tie into existing raw water lines.

Since it began treating with ozone, ARJWS has received zero complaints related to ozone throughout its 15 member agencies, and the 200,000 constituents drinking the water throughout Anderson and Pickens counties. MIB and Geosmin concentrations are now below detection, and treatment efficiency has improved with increased TOC removal, reduced alum usage and reduced operation and maintenance costs.